We present full thesis focusing on SysML and MBSE adoption on one of the most used documents in the industry – Vehicle Feature Code Matrix (VFCM). Note The Master of Science in Product Development program (University of Detroit Mercy) is developed in cooperation with five major U.S. corporations and focused specifically on the automobile industry and targets experienced engineers that will lead product development/ manufacturing activities into the 21st century.

Introduction

Vehicle complexity management is one of the most challenging topics in the Automotive Industry. In the past, vehicle manufacturers offered the market unique models with the small variety of options. Nowadays, with all the emerging technology and consumer-oriented markets, vehicle feature packages become more and more complex. The complexity management has become a very challenging task for the OEMs’ manufacturing.

Some Highlights

Conclusions

“SysML Approach creates a very elegant solution which is game-changer for automotive industry“.

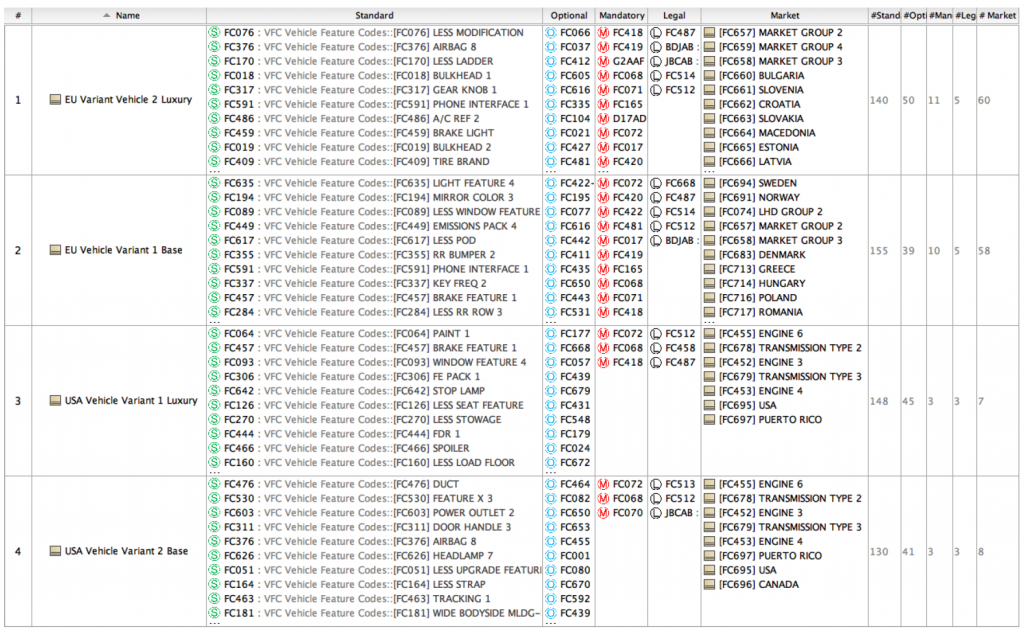

We have reviewed the advantages of the system modeling compared with the “document-based” approach for the Vehicle Feature Complexity Matrix. The Proof of Concept presented in this research has demonstrated the potential to meet the function of representing and communicating the vehicle program feature deployment direction to the interested parties, increase the efficiency, robustness and minimize the undesired behaviors in the VFCM.

The VFCM model can improve the consistency of the information, reduce the amount of resources dedicated to maintain and update the feature directions, and provide a greater capability to display the information in tables, matrices and diverse diagrams that can also be customized to define the scope of the analysis, so the user looks specifically at what is needed in order to make an informed decision, evaluate or propose a feature change.

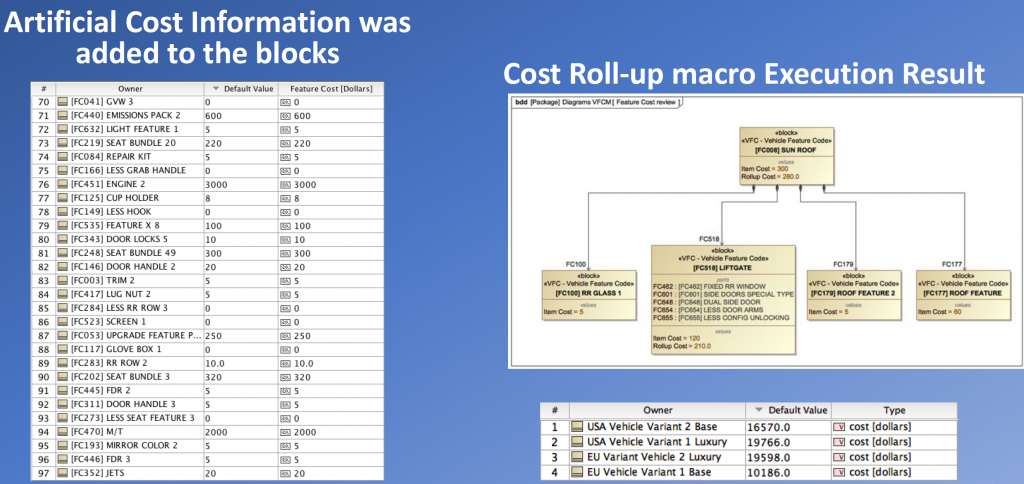

The system modeling of the VFCM opens new possibilities to expand the current functionality to integrate other processes as we have reviewed with the Cost Roll-up Analysis which uses the existing model to produce new valuable information for the stakeholders. Beyond what we have discussed in this project there is still a wider field to expand the capabilities for creating new reports or model tools to attend to specific needs of VFCM users like functional or engineering attribute teams, marketing and finance teams.

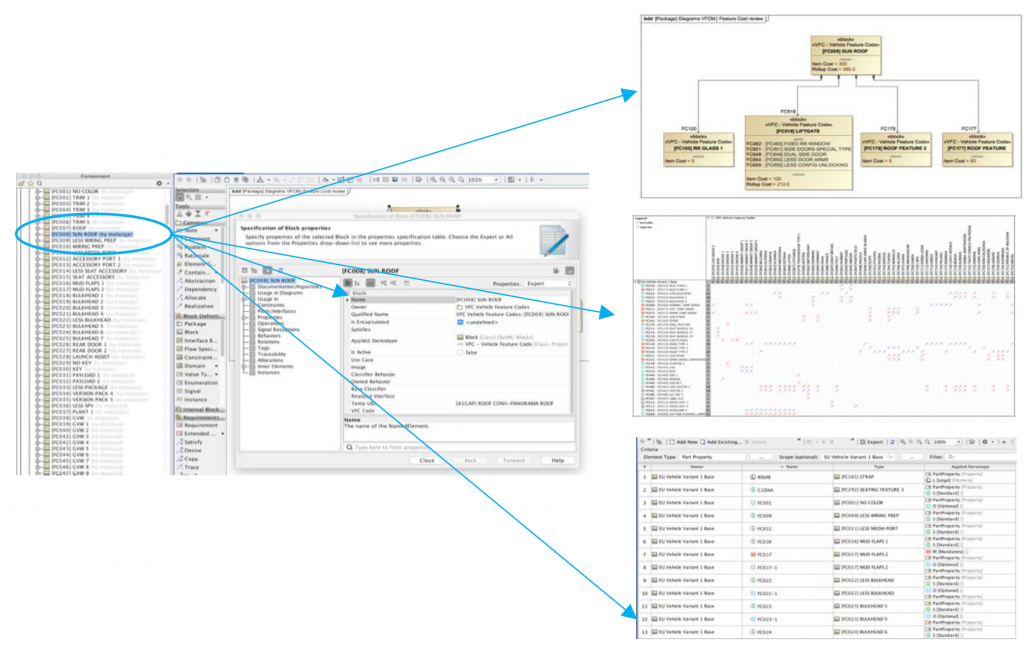

The modeling tool used in this thesis project was MagicDraw. It proved to be very capable and robust to manage big and complex networks of highly interconnected blocks as reviewed in this project. The software interface is convenient and highly customizable to be able to import information easily, build diagrams, tables and matrices very quickly and efficiently. This modeling tool offers great advantages to manage the VFCM proof of concept model and we consider that its capability can be extrapolated to a larger scale to VFCM models in real life automotive vehicle programs.

As a further step to continue this development a joint project with an OEM would be required in order to launch a pilot model using real vehicle program information, getting interaction with the users and feedback from all the stakeholders. This will help to apply this Proof of Concept to a real world application and to make a deeper evaluation of the effectiveness and the benefits of VFCM system model.

Presentation

Thesis

Program

Master of Science in Product Development, University of Detroit Mercy Master Thesis

The Master of Science in Product Development was developed in cooperation with Massachusetts Institute of Technology and five major U.S. corporations. The program is focused specifically on the automobile industry and targets experienced engineers that will lead product development/manufacturing activities into the 21st century. The program features intense classroom interactions with an array of seminars and case studies conducted in conjunction with partner companies. The curriculum is challenging and rigorous. The program is beneficial for both product and manufacturing personnel – product development, manufacturing, research, quality, and supply management among others.

http://www.udmercy.edu

Authors

PRESENTED BY: Jesus Mata Castañeda, Natalie Matevossyan

Advisor, Michael Vinarcik